Fully let out technique is about cutting a pelt into thin diagonal strips and then stitching them back together to create a longer and more narrow strip that runs the full length of the coat. This results in more uniformity regarding density and enhanced "swinging motion" of the garment since each stitch acts as a small joint. Furthermore, if needed, thin leather stripes can be inserted between the fur strips to reduce density and volume of fur, especially in very thick fur types and this is called feathering. In mink fur, letting out is commonly used to produce long fur coats that look seamless as opposed to skin to skin fur stitching.

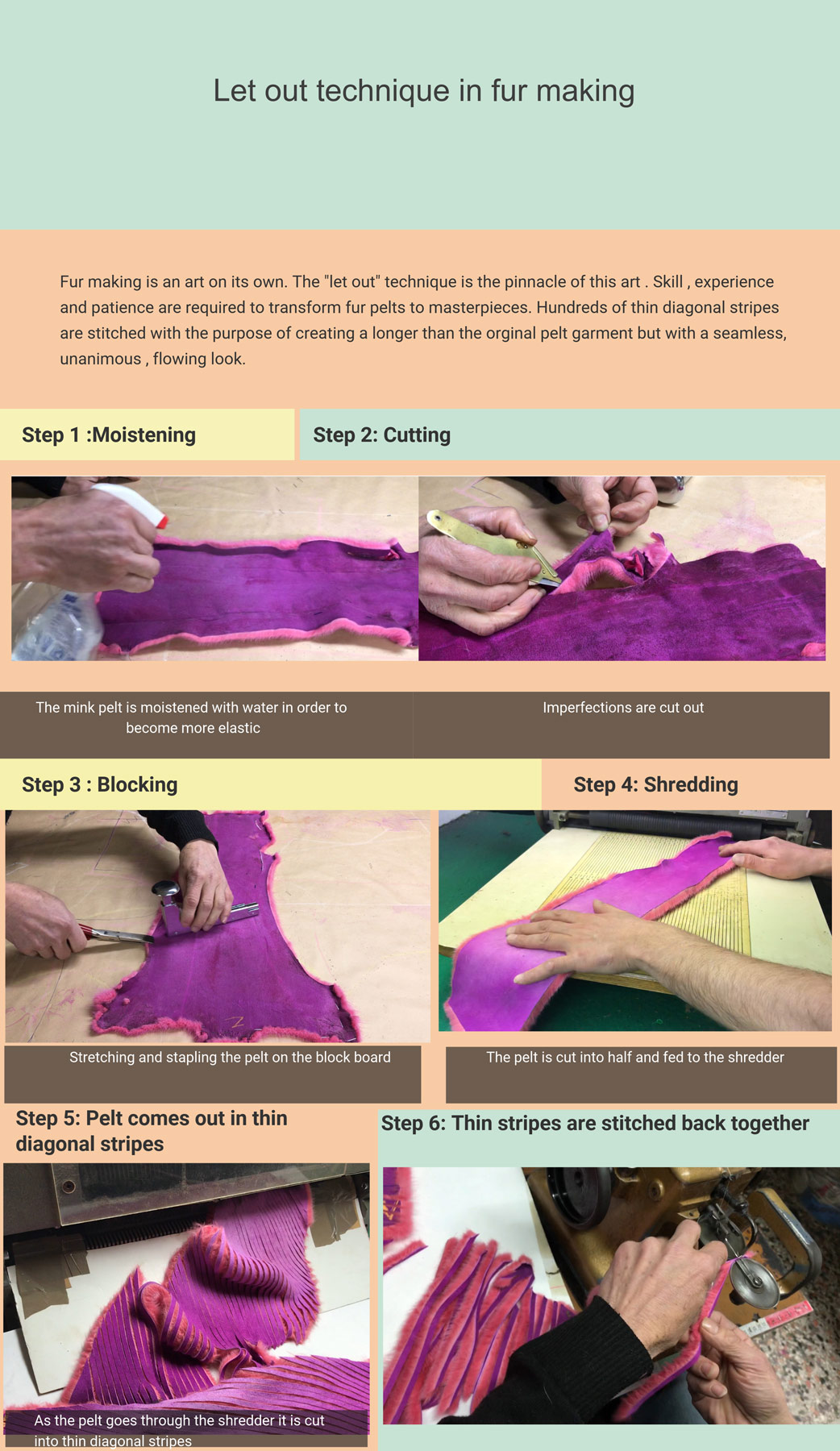

Step 1: The mink pelt is sprayed with water so that i becomes more elastic.

Step 2: Imperfections are cut out

Step 3: The mink fur pelt is stapled on a block board

Step 4: The pelt is cut into halves and fed to the shredder

Step 5: Coming out of the shredder into thin diagonal stripes

Step 6: The diagonal stripes are stitched back together in a "arrow point" shape. This results in elongation and narrowing of the pelt.

From then on standard fur making procedure is followed untill the let out pelts are made into a ready to wear mink fur coat.

The let out stithing technique is shown in the video below:

-

2

2

-

1

1